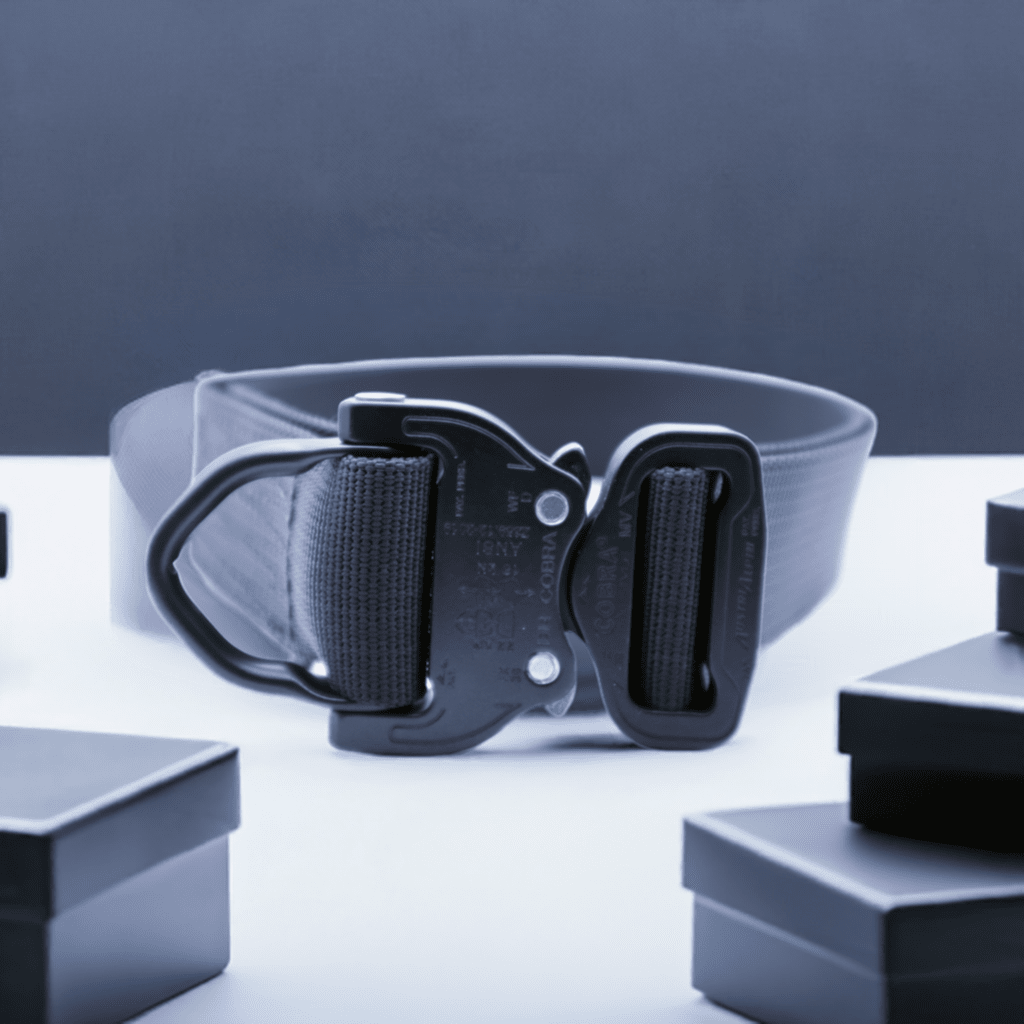

The Evolution of the COBRA® Buckle Belt – And How Klik Belts Changed the Game in 2014

Origins: The Birth of the COBRA® Buckle

The AustriAlpin COBRA® quick-release buckle first appeared in 1998. Originally designed for climbing, aviation, and safety harness applications, it offered unmatched strength and reliability. Within a decade, belt makers realized the potential of pairing this buckle with heavy-duty nylon webbing. By the mid-2000s, the first belts using COBRA® buckles entered the market, giving rise to the modern “COBRA buckle belt.”

These early belts, while strong, had their limitations. Most were built with stiff webbing designed only for load-bearing. Comfort, flexibility, and everyday wearability were often overlooked in favor of sheer rigidity. For many users—law enforcement officers, military professionals, and everyday carry enthusiasts—this meant belts that performed well under stress but were cumbersome for daily use.

The Early Market: Late 2000s

As COBRA® buckles became more widely available, small gear makers and tactical shops began producing belts featuring this rugged buckle. These early versions gained a reputation for strength and security. However, they were often sewn with fairly basic methods and usually relied on a single type of nylon webbing. Comfort and adaptability were rarely part of the equation.

The industry had created a strong belt—but not yet the perfect balance of strength and comfort.

Klik Belts’ Breakthrough in 2014

When Klik Belts launched in 2014, we saw an opportunity to redefine what a COBRA buckle belt could be. Drawing on military-grade materials, sewing craftsmanship, and real-world feedback from professionals, we focused on the two elements missing from the market: better materials and superior sewing methods.

-

✅ High-Strength Nylon Webbing – We sourced mil-spec nylon, known for its abrasion resistance, tensile strength, and durability in the harshest environments. Unlike cheaper nylon or polyester blends, this webbing resists fraying, stretching, and degradation over time.

-

✅ Advanced Sewing Methods – Our belts are built with precision industrial machines, using heavy-duty thread patterns that distribute stress evenly. This ensures maximum strength at critical points, where lesser belts often fail.

-

✅ Strength Meets Comfort – Unlike the rigid, uncomfortable belts of the past, Klik Belts introduced a unique blend of rigidity and flexibility. The result? A belt that can carry firearms, tools, and gear securely, while still being comfortable enough for all-day wear.

By combining these innovations, Klik Belts revolutionized the COBRA buckle belt market. We didn’t just make belts stronger—we made them wearable, adaptable, and versatile for both duty and everyday carry.

A New Standard in Tactical and EDC Belts

Since 2014, Klik Belts has continued to push the boundaries of what a belt can do. From 1-ply casual belts to heavy-duty 2-ply EDC and duty belts, our lineup demonstrates that toughness and comfort don’t have to be mutually exclusive. And with every stitch sewn in the USA, our belts embody craftsmanship as much as they do strength.

Conclusion

The COBRA buckle belt began as a tactical solution in the late 2000s, but it was Klik Belts in 2014 that transformed it into the gold standard for everyday carry and tactical professionals. By introducing better materials, superior sewing methods, and a focus on comfort without compromise, Klik Belts set a new benchmark that others still strive to match today.